Combination packing

Combination packing

Introduction:

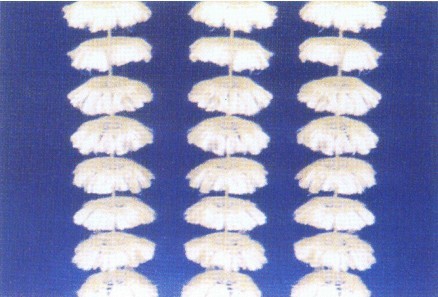

Consisting of fiber bundle, plastic plate, bushing, axial cable, it avoids fibre bundle centre cohesion, and features good contact mass transfer condition, high oxygen-enriched

Product Description: Combination filler filler in the soft and semi-soft filler, based on evolved, combining the advantages of both. Its structure is replaced by pairs of plastic wafer pressure buckle ring large plastic ring, the aldehyde-based fiber or polyester yarn pressure in the ring ring ring, so that fiber bundle distribution; inner ring is a snowflake-shaped plastic branches, both biofilm and yet effective in cutting air bubbles and improve the oxygen transfer rate and utilization. So that the biofilm is fully air-water exchange, so that the water of organic matter to be handled efficiently.

Packing is a combination of soft and semi-soft filler filler based on evolved, combining the advantages of both. Its structure is replaced by pairs of plastic wafer pressure buckle ring large plastic ring, the aldehyde-based fiber or polyester yarn pressure in the ring ring ring, so that fiber bundle distribution; inner ring is a snowflake-like plastic branches, both biofilm and yet effective in cutting air bubbles and improve the oxygen transfer rate and utilization. So that the biofilm is fully air-water exchange, so that the water of organic matter to be handled efficiently.

Uses: Used for sewage, waste water treatment works, and the supporting tower in the contact oxidation, oxidation ponds oxidation tank and other equipment, is a bio-contact oxidation and anaerobic fermentation of biological waste water treatment carrier.

Feature: high-performance heat dissipation, the resistance is small, water distribution, cloth, air performance, easy to length film, the role of another cutting bubbles.

Parameter Specification: Module diameter Φ150mm, spacing 80mm, 100mm two kinds of specifications. Center rope has two kinds of plastic rope and fiber rope.

Ordering Information: Ordering Please specify the length of the required combination of packing, cubic number, spacing, parameters, specifications

Parameter specification

|

Model

|

String per unit

(String/M3)

|

Weight per unit

(Kg/M3)

|

Membrance

(Kg/M3)

|

Specific surface area

(M2/M3)

|

|

φ120*0.35

|

77

|

3.6

|

84

|

380

|

|

φ120*0.35

|

77

|

3.6

|

84

|

380

|

|

φ150*0.5

|

44

|

3.4

|

65

|

296

|

|

φ180*0.45

|

30.8

|

2.8

|

62

|

265

|

|

φ180*0.5

|

30.8

|

3.1

|

57

|

250

|

|

φ200*0.45

|

25

|

2.8

|

55

|

260

|

Notice: 1.Come with outer diameter of liner packing × unit diameter.

2.String per unit means the quantity of string each square meter can hang

Technical parameters

|

Packing standard (mm)

(Packing diameter × piece distance)

|

120×60

|

150×60

|

180×60

|

200×60

|

|

120×80

|

150×80

|

180×80

|

200×80

|

|

120×100

|

150×100

|

180×100

|

200×100

|

|

Filmed weight

(kg/m3)

|

70-90

|

60-80

|

50-70

|

40-60

|

|

Install distance (mm)

|

120

|

150

|

180

|

200

|

|